- Home

- About us

- Products

- Thermal Laminating Films

- Cold Stamping Foils

- Polyolefin shrink film

- Pouch Laminating Film

- Hot Stamping Foils

- Adhesive Glue & UV Inks

- Roll Laminating Film

- Flexible Plastic Packaging Films

- Gloss Laminating Film

- Matte Lamination Film

- Soft Touch Lamination Film

- Scratch Resistant Film

- Metalized Polyester Film

- Post-press Finishing Supplies

- Faqs

- News

- Certificate

- Contact us

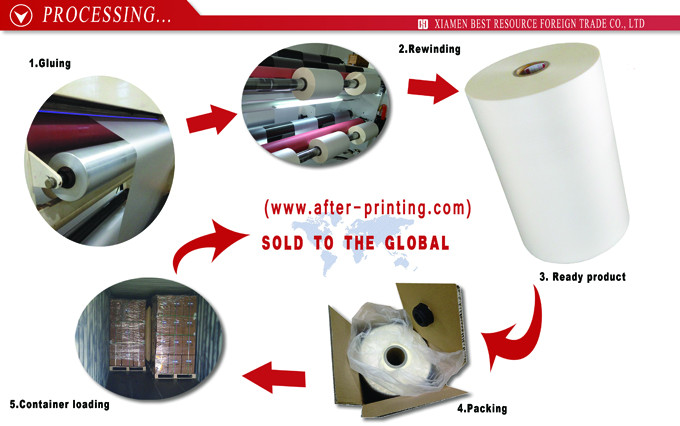

More Information About BOPP Lamination Film, Capacity, Sample delivery, Packaging & Shipping

![]() What’s BOPP Thermal Laminating Film?

What’s BOPP Thermal Laminating Film?

BOPP Thermal Laminating Film is an environmental packing material which enhances the finished item's value through high transparency and super luster finish.

It could prevent lamination from being pressed, bubbled and desquamated.

BOPP Thermal Laminating Film could also protect from harmful substances and water-proof, ensuring a long life storage for the printings.

Particularly, matte BOPP thermal laminating film is good for UV varnishing and hot stamping as it has double corona treatment valued over 42dynes.

To be specific, this product is subject to plastic film roll with adhesive that is being laminated onto covers of paper substrates.

It is mainly consisted of BOPP+EVA.

BOPP, abbreviation of biaxially oriented polypropylene, is the base film that we use extrusion coating process to produce BOPP thermal laminating plastic film rolls.

EVA, abbreviation of Ethyl Vinyl Acetate, is the adhesion combined with BOPP plastic Film that enable a thermal laminating film roll adhesive.

As a Chinese manufacturer and supplier BOPP Thermal Laminating plastic Film Roll, we serve its both types of glossy and matte whose thickness can be made from 17micron to 30micron.

Frequently used thickness of BOPP thermal laminating film including; 17mic, 20mic, 22mic, 25mic, 27mic

![]() Where is BOPP Thermal Laminating Film Used?

Where is BOPP Thermal Laminating Film Used?

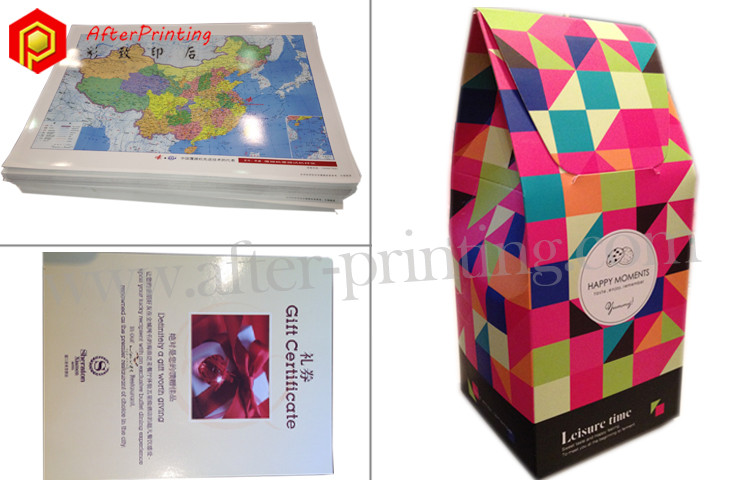

The application of BOPP Thermal Laminating Plastic Film Roll can be used to the followings:

Textbook covers | Brochures | Leaflets | Sweet boxes | Cosmetics | Shopping bags | Diaries

The paper materials to be laminated with thermal laminating film can be glossy art paper, white or brown Kraft paper,cardboard paper, and fancy paper.By thickness, it is suitable for 128gsm,157gsm and 200gsm art paper, 250gsm to 300gsm cardboard paper, and 100gsm to180gsm Kraft paper.

The printing types suitable for thermal laminating film can be offset CMYK printing, digital printing, flexographic printing,gravure intaglio printing, relief printing, as well as screen-printing that includes printing machines of horizontal-lift, swing cylinder and stop cylinder screen printing machines.

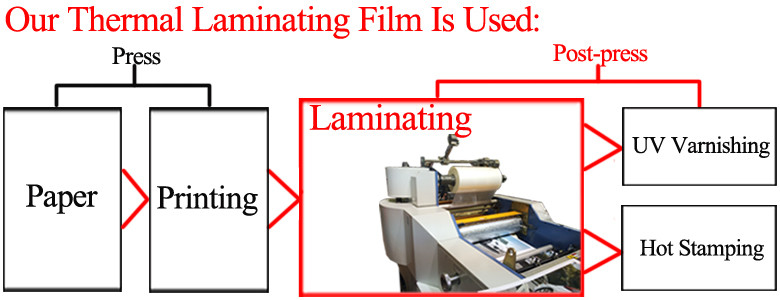

As the post press finishing supplying,thermal laminating film is also used to UV varnishing and hot stamping with various colors or patterns.

![]() How to use BOPP Thermal Lamination Film?

How to use BOPP Thermal Lamination Film?

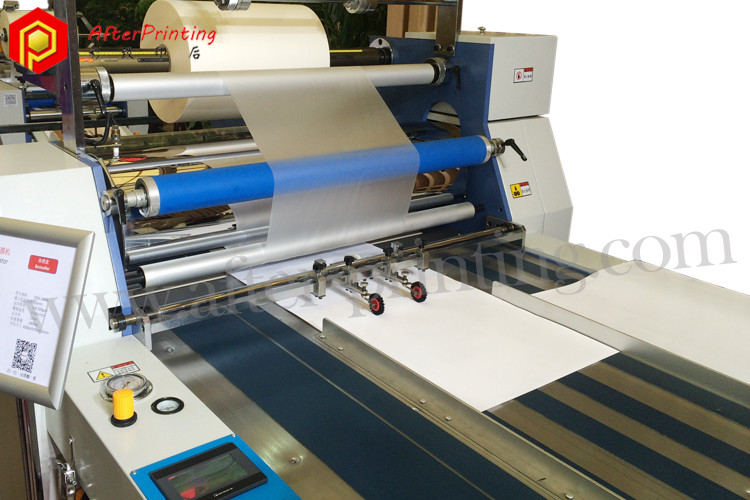

Lamination process is of joining two or more layers, aimed for protecting the prints.we need a hot laminator, or called thermal (heat,dry) lamination roller machine, to use BOPP Thermal Lamination Plastic Film Roll by melting its EVA adhesive onto paper surface.During the process, the BOPP thermal plastic film roll is passed on a heated roller and under reasonable pressure it sticks to the paper.This process is easy to use and can be done in home for small applications.Sometimes, people also call it heat lamination or dry lamination or hot lamination.

![]() Operation Guidance

Operation Guidance

1. Adjust roller pressure and temperature according to different types of paper and ink.

2. When using the film for the first time or changing the usual size, a small trial volume before

starting massive lamination is proposed.

3. Normal process temperature is 90 ℃ ~105 ℃ (203 ℉ ~ 221 ℉), roller pressure and temperature

vary from different types of paper, ink and machines.

4. Make sure the ink is dry before laminating. It will delaminate when the paper contains too much

moisture or powder.

5. Make sure to put the material in place with low temperature and dry.

6. The following situation will affect the final quality of the film during lamination.

a. Using metal ink b. Much too thick ink c. Ink completely not dried yet.

d. Much too humid paper sheet. e. Too much powder on the surface

f. Ink containing too much wax, dried oil, adhesive, silicon additive and so on.

![]() About Responsibility & Our Promise

About Responsibility & Our Promise

*Pre-sale: response within 24h, samples within 5 days, payment protection

*In-sale: offer manufacturing schedule; quality protection

*After-sale: 9 months warranty, Guides to various equipments and technology

*In case of any quality problem happens, you must be equivalently compensated

![]() About Sample & Delivery

About Sample & Delivery

*Samples for testing are available and free

*Usually sized 400 mm*100 m/200 m(thickness upon requirement)

*The freight for sample delivery is at receivers' side

*But to be refunded by deducting from the right coming order automatically

*For saving the cost, we recommend the way of prepaid instead of collect

![]() About Capacity

About Capacity

*2 coating lines of 350 MTs per month

*20 days delivery of a 40 feet container

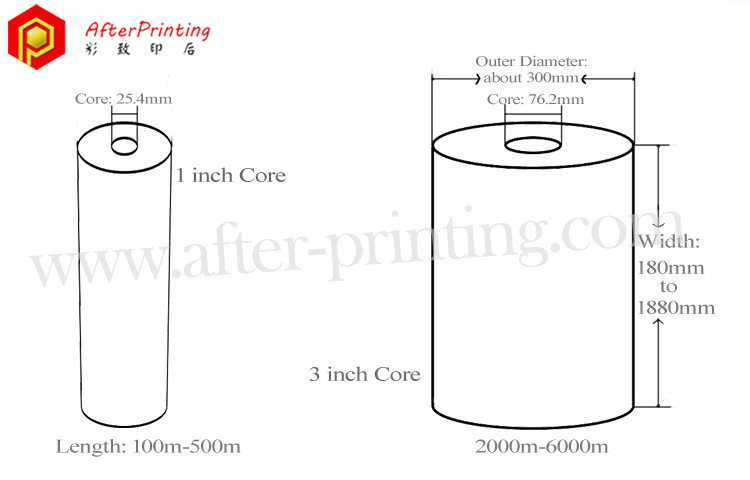

*Reel inner diameter at 25.4 mm(1 inch) or 76.2 mm(3 inch)

*Reel outer diameter: 240 mm to 380 mm(upon reel length and width)

![]() Packaging & Shipping

Packaging & Shipping

* One roll BOPP thermal lamination film, one carton

* Tens of rolls of BOPP thermal lamination film in a pallet

* 10 to 12 pallets loaded into 1*20FCL (appro. 13 MTs)

* Or 20 to 22 pallets loaded into a 40 feet container (appro. 25 MTs)

* Seaport: Xiamen, Shanghai, Ningbo

Airbags Used for Protecting the Pallets from Collision When Container is Loading…