- Home

- About us

- Products

- Thermal Laminating Films

- Cold Stamping Foils

- Polyolefin shrink film

- Pouch Laminating Film

- Hot Stamping Foils

- Adhesive Glue & UV Inks

- Roll Laminating Film

- Flexible Plastic Packaging Films

- Gloss Laminating Film

- Matte Lamination Film

- Soft Touch Lamination Film

- Scratch Resistant Film

- Metalized Polyester Film

- Post-press Finishing Supplies

- Faqs

- News

- Certificate

- Contact us

What is Hot Stamping and Foil Stamping

Hot Stamping

Hot stamping is a dry printing method of lithography in which predried ink of foils are transferred to a surface at high temperatures.

Process

In a hot stamping machine, a die is mounted and heated, with the product to be stamped placed beneath it. A metallized or painted roll-leaf carrier is inserted between the two, and the die presses down through it. The dry paint or foil used is impressed into the surface of the product. The dye-stamping process itself is non-polluting because the mateirals involved are dry.

Tools

Among the commonly used tools in hot stamping are dies and foil. Dies may be made of metal or silicone rubber, and they maybe shaped directly or cast. They can carry high levels of detaol to be transferred to the surface and may be shaped to accommodate irregularities in the surface.

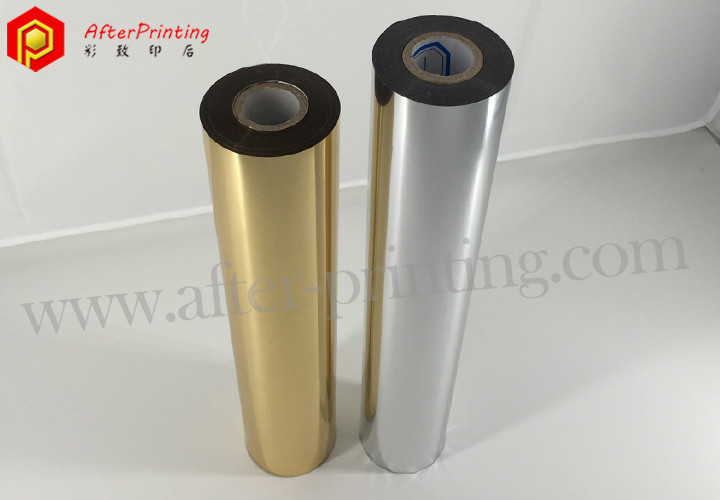

Foils are multilayered coating that transer to the surface of the product. Non-metallic foils consist of an adherence base, a release layer, a color layer, and a adhesion layer. Metallic fiols replace the color layer with a layer of chrome or vacuum-metallized aluminum. Metallic foil construction has a metal-like sheen and is available in different metal shades such as gold, sivler. Pigment foil does not have a metalic sheen but may be glossy or matte. Holographic foil paper includes a 3-dimensional image to provide a distinctive appearance to specific areas of a digitally printed application.

Foil Stamping

Foil stamping, also known as foil application, typically a commercial printing process, is the application of metallic or pigmented foil on to a solid surface by application of a heated die onto foil, making it permanently adhere to the surface below leaving the design on the dye. In the process known as hot foil stamping, foil stamping machines uses heat to transfer metallic foil to a solid surface.Example of items that are foil stamped include annual reports, pocket of folders, product packaging, note cards/thank you cards, business cards, envelopes and letter head. The foil stamp is a permanent process.

Type

There are two primary types of foil stamping machines. The first type is manual and the second is pneumatic(air powered), which typically used in a commercial print shop. Manual foil stampers are ideal for low jobs and the pneumatic is ideal for medium to high-volume jobs.

Commercial foil stamping is usually produced on a Kluge foil stamp press or a Heidelberg Windmill retro fitted for foil stamping.

Foil

Foils come in a wide selection of colors and finishes, from the most commonly used metallic gold and silver to foils with pearlescent and holographic effects.