- Home

- About us

- Products

- Thermal Laminating Films

- Cold Stamping Foils

- Polyolefin shrink film

- Pouch Laminating Film

- Hot Stamping Foils

- Adhesive Glue & UV Inks

- Roll Laminating Film

- Flexible Plastic Packaging Films

- Gloss Laminating Film

- Matte Lamination Film

- Soft Touch Lamination Film

- Scratch Resistant Film

- Metalized Polyester Film

- Post-press Finishing Supplies

- Faqs

- News

- Certificate

- Contact us

Matte Soft Touch Thermal Lamination Film Roll for Luxury Packaging

- FOB Price

US $0.4620,000 - 60,000 square meter

US $0.4360,001 - 130,000 square meter

US $0.39130,001 - 250,000 square meter

- group name

- Soft Touch Thermal Laminating Film

- Min Order

- 20000 square meter

- brand name

- AfterPrinting

- Nearest port for product export

- Xiamen, Shanghai, Ningbo, Qingdao

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, DDP, DDU, Express Delivery

- Acceptable payment methods

- T/T, L/C, D/P D/A, PayPal, Westem Union, Cash

- Export mode

- Have the independent export and import right

- update time

- Wed, 02 Nov 2016 10:49:23 GMT

Paramtents

Material BOPP+EVA

Transparency Transparent

Corona Treatment 42 Dynes (single or double sides)

MOQ 2,000 Kgs (consolidated roll widths accepted)

Delivery Lead 20 Days

Thickness 30μm,32 μm,35 μm,39 μm,42 μm, etc

Roll Width 180 mm to 1880 mm (like 305 mm, 457 mm, etc.)

Roll Length 300 m (1" core), 2000 m/3000 m/4000 m (3" core)

Paper Core 1 inch (25.4 mm), 3 inch (76 mm), 6 inch (152 mm)

Joint ≤1

Packging & Delivery

-

Min Order20000 square meter

Briefing

Detailed

Matte Soft Touch Thermal Lamination Film Roll for Luxury Packaging

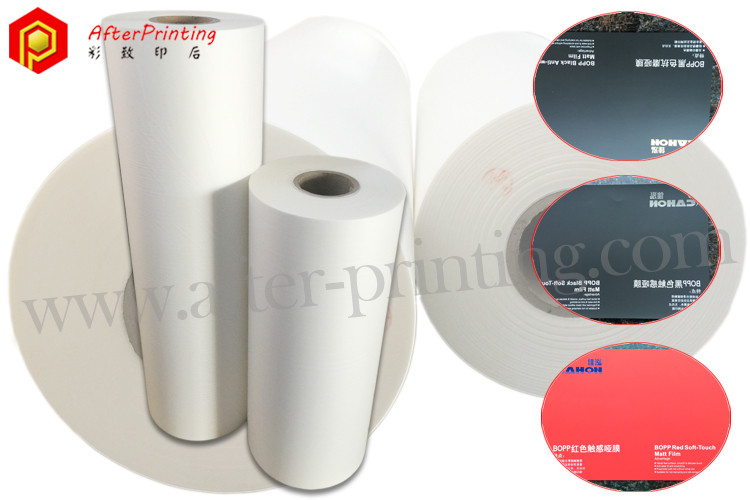

Soft Touch Thermal Laminating Film is seen as luxury packaging material for cosmetic. This is the first film with tactile properties in history and presents a pleasant and intense velvety effect very similar to the peach skin. An exceptional product among plastic films in search of a touch distinction. Soft Touch Thermal Laminating Film is printable, glue-able and stamp-able.

The matte side has en excellent soft touch effect as well as a high dyne level for improved printability.

Soft Touch Thermal Laminating Film is widely used in the luxury packing industry such as business card, luxury cosmetic, etc.

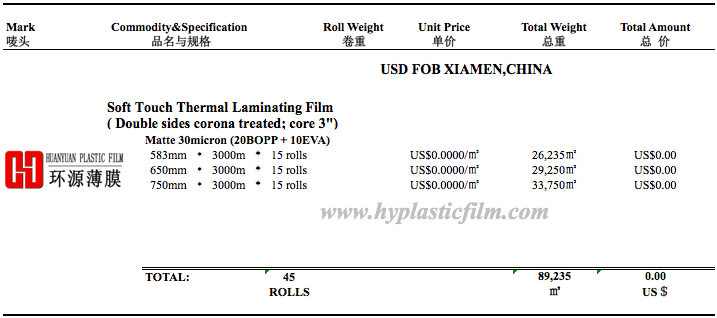

| PRODUCT DETAILS | Item NO. | AFP-S30 | AFP-S31 | AFP-S32 | AFP-S33 | AFP-S34 |

| Type | Matte | Matte | Matte | Matte | Matte | |

Thickness (micron) | BOPP | 23 micron | 23 micron | 23 micron | 23 micron | 23 micron |

| EVA | 7 micron | 8 micron | 9 micron | 10 micron | 11 micron | |

| Total | 30 micron | 31 micron | 32 micron | 33 micron | 34 micron | |

| Yield | m²/kg | 37.936 | 36.101 | 34.916 | 33.807 | 0.0296 |

| kg/m² | 0.0264 | 0.0277 | 0.0286 | 0.0296 | 0.0305 | |

| Thickness Tolerance | ±1 micron | |||||

| Width | 180 mm ~ 1880 mm (±3 mm) | |||||

| Length | 150 ~ 300 m; 2000 m ~ 6000 m | |||||

| Paper Core | 25.4mm(1inch), 76.2mm(3inch) | |||||

| Joint | ≤1 | |||||

| Corona Treatment | one side or double sides | |||||

| Surface Tension | ≥42 dynes | |||||

![]() Features

Features

* Exceptional velvet sense

* Soft touch

* Silk feeling

* Designed for high quality graphic media

* For luxury packaging

* Well applied to digitally printed media

* Enhance outstanding effect, distinguished from other prints.

Tips: you are able to take an order of Soft Touch Thermal Lamination Film like this:

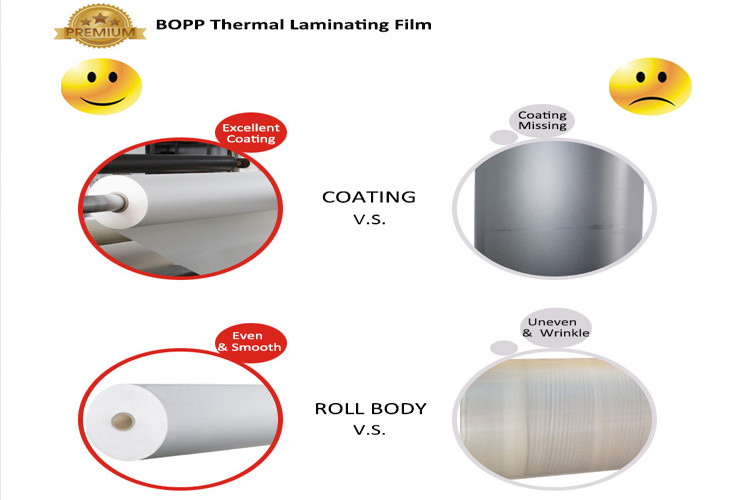

In order to secure a long cooperation relationship with each customer, we guarantee serving high product quality by carrying out very strict management from raw material to packaging details. the following is the comparison conducted between our bopp thermal laminating film roll quality and other manufacturers.

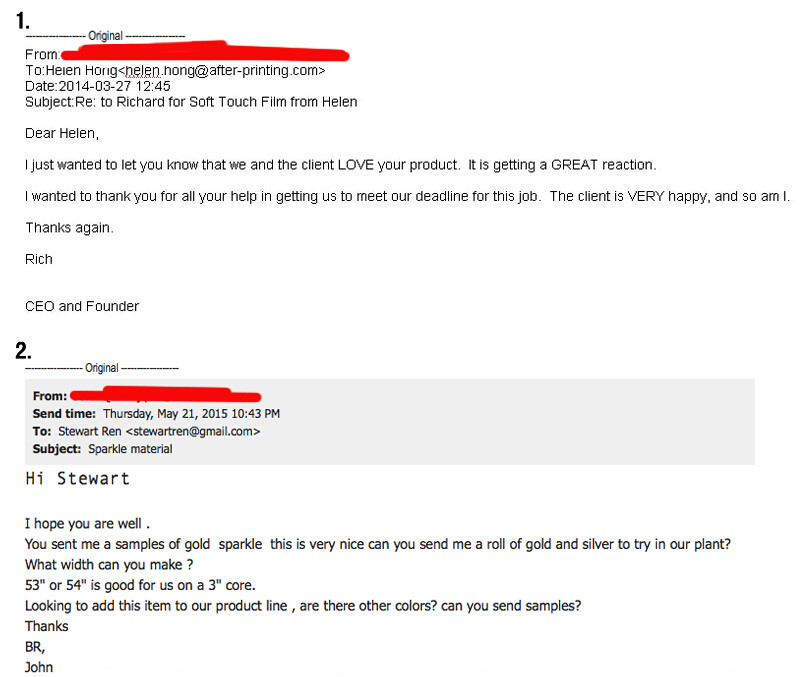

The following real feedbacks are directly given by customers after sample testing or a shipment usage.

![]() About Capacity

About Capacity

* 2 coating lines

* 20 days delivery of a 40 feet container

* 350MTs per month

* Thickness from 30 micron to 42 micron

* Roll width from 180mm to 1880mm

* Roll length from 150 m to 6000 m

* Reel inner diameter at 25.4 mm (1 inch) or 76 mm (3 inch)

* Reel Outer Diameter: 240 mm to 380 mm (upon reel length and width)

![]() About Samples

About Samples

* Samples for testing are available and free

* Usually sized 400 mm*100 m/200 m

* For favorite measures, please feel free to advise

![]() About Freight

About Freight

* The freight for sample delivery is at receiver’s side

* But to be refunded by deducting from the right coming order automatically

* For saving the cost, we recommend the way of prepaid instead of collect

![]() Packaging & Shipment

Packaging & Shipment

* One Roll Soft Touch thermal lamination film, One carton

* Tens of rolls of Soft Touch thermal lamination film in a pallet

* 10 to 12 pallets loaded into 1*20 FCL (appro. 13 MTs)

* Or 20 to 22 pallets loaded into a 40 feet container (appro. 25 MTs)

* Seaport: Xiamen, Shanghai, Ningbo

Air Dunnage bags Used for Protecting the Pallets from Collision When Container is Loading…

![]() About After-sale-service

About After-sale-service

* 6 months warranty

* In case of any quality problem happens, you must be equivalently compensated

![]() Where is Soft Touch Thermal Laminating Film Used?

Where is Soft Touch Thermal Laminating Film Used?

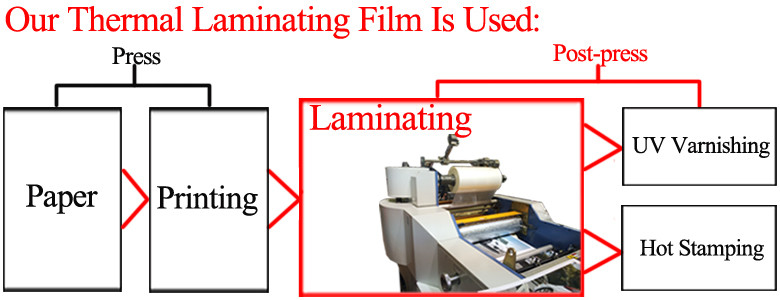

Soft Touch Thermal Laminating Film is widely used in the custom packing industry as well as for high-end book covers, packing prototypes, corporate brochures, product branding as well as a variety of other quality graphic solutions. It is also applied to digitally printed media.

The paper materials to be laminated with thermal laminating film can be glossy art paper, white or brown Kraft paper,cardboard paper, and fancy paper.By thickness, it is suitable for 128gsm,157gsm and 200gsm art paper, 250gsm to 300gsm cardboard paper, and 100gsm to180gsm Kraft paper.

The printing types suitable for thermal laminating film can be offset CMYK printing, digital printing, flexographic printing,gravure intaglio printing, relief printing, as well as screen-printing that includes printing machines of horizontal-lift, swing cylinder and stop cylinder screen printing machines.

As the post press finishing supplying,thermal laminating film is also used to UV varnishing and hot stamping with various colors or patterns.

![]() How to use Soft Touch Thermal Lamination Film?

How to use Soft Touch Thermal Lamination Film?

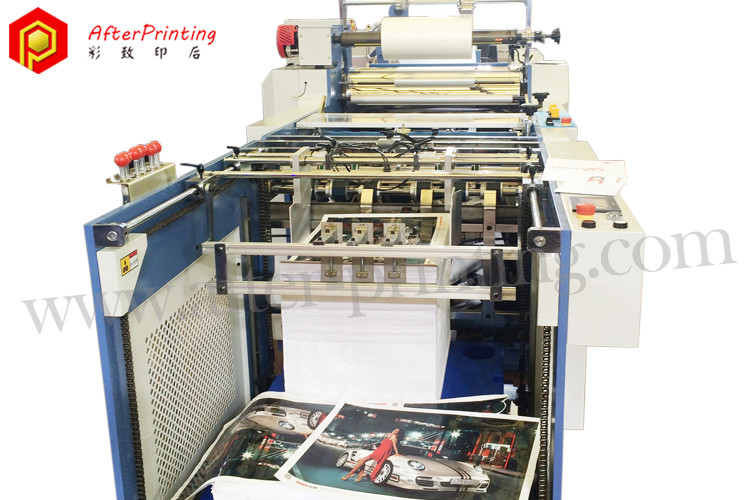

Lamination process is of joining two or more layers, aimed for protecting the prints.we need a hot laminator, or called thermal (heat,dry) lamination roller machine, to use BOPP Thermal Lamination Film by melting its EVA adhesive onto paper surface.During the process, the BOPP thermal film is passed on a heated roller and under reasonable pressure it sticks to the paper.This process is easy to use and can be done in home for small applications.Sometimes, people also call it heat lamination or dry lamination or hot lamination.

![]() Operation Guidance

Operation Guidance

1. Adjust roller pressure and temperature according to different types of paper and ink.

2. When using the film for the first time or changing the usual size, a small trial volume before starting massive lamination is proposed.

3. Normal process temperature is 90℃ ~ 105℃ (203℉ ~ 221℉), roller pressure and temperature vary from different types of paper, ink and machines.

4. Make sure the ink is dry before laminating. It will delaminate when the paper contains too much moisture or powder.

5. Make sure to put the material in place with low temperature and dry.

6. The following situation will affect the final quality of the film during lamination.

a. Using metal ink b. Much too thick ink c. Ink completely not dried yet.

d. Much too humid paper sheet. e. Too much powder on the surface

f. Ink containing too much wax, dried oil, adhesive, silicon additive and so on.